[et_pb_section admin_label=”section”][et_pb_row admin_label=”row”][et_pb_column type=”4_4″][et_pb_text admin_label=”Text”]

While most of the time I write about products made from 100% recycled rubber, this week I decided to change it up a bit and write about something that most of use every day – an aluminum can. I always like to put things into perspective as to why it is important that we recycle as much as we can to better the earth.

We use a lot of aluminum cans each year…I mean a lot! 80,000,000,000 cans are used on average each year in the United States. Of these 80 billion, we currently recycle more than 58% of them, but that still means far too many are heading to landfills across the country.

Aluminum cans – the facts:

On average, Americans drink one beverage from an aluminum can every day.

An aluminum can is able to be returned to the shelf, as a new can, as quickly as 60 days after it’s put into your recycling container.

If you stacked all of the aluminum cans recycled last year on top of the other, it would be 1,454 times taller than the Empire State Building.

If you laid all the aluminum cans recycled last year end to end, they could circle the earth 169 times!

Coast-to-coast, there are about 10,000 locations that buy aluminum, making it easy for Americans to redeem their used beverage cans for cash. In fact, recycling aluminum cans is a $1 billion/year industry in this country.

Recycling one aluminum can saves enough energy to run a television for three hours.

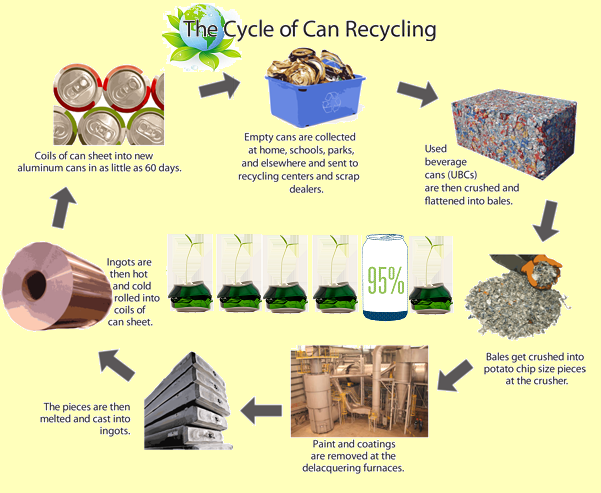

A Day in the Life of a Recycled Can:

1. Customer takes can to a recycling center or puts it into a recycling bin.

2. The can is transported to a processing facility.

3. A giant magnet lifts out cans that are made of metals such steel. Since aluminum cans aren’t magnetic, they drop down to a conveyor belt and are gathered.

4. The aluminum is shredded, washed and turned into aluminum chips.

5. The chips are melted in a large furnace.

6. The melted aluminum is poured into molds called “ingots.”

7. The ingots are taken to a factory where they’re melted into rolls of thin, flat sheets.

8. From the sheets, manufacturers make new products, including new beverage cans, pie pans, license plate frames, and aluminum foil.

9. Beverage companies fill the cans and deliver them to grocery stores for customers to purchase.

10. Customers take used cans to a recycling center and the process starts all over again.

So the next time finish your favorite drink it that aluminum can think twice about just tossing it in the trash – who knows, you may be drinking out of part of it again in just a few months!

[/et_pb_text][/et_pb_column][/et_pb_row][/et_pb_section]